With so many different options out there for decorating your custom apparel or promotional products, how do you know when to use each method? Each decoration option comes with certain pros and cons as well as some limitations. To make things easy, most of our products have a recommended or default decoration method and our dedicated team are always here to assist you if you have any questions. To make things even easier, the custom logo experts have broken down the major decoration techniques below. Jump to the decoration type you want to learn more about using the links below and click into each section for more information on our custom capabilities for each decoration type!

|  |  |

|  |  |

|  |  |

|  |  |

Screen Printing

Screen printing utilizes different types of brightly colored inks and is often used for printing posters and other promotional items. Initially, screen printing was confined on silk materials. Nowadays, several different types of materials are used. During the screen printing process, a design is laid on the top of the screen. Thereafter, it is covered with photo emulsion and exposed to light. Due to its exposure to heat, the emulsion hardens up and the rest of it is washed away by leaving one kind of a stencil whose ink can be pulled by using a squeegee.

Screen Printing is Ideal for…

- Screen Printed Electronics

- Custom T-Shirts

- Custom Active wear & Sports Apparel

- Screen Printed Sweatshirts & Hoodies

- Promotional Pens & Custom Printed Notebooks

- Custom Drinkware

- Custom Golf Balls

- Much more

Pros of Screen Printing as a Decoration Method

- Most cost effective decoration method for larger custom apparel orders.

- Just about any design and ink color can be applied to any product through screen printing.

- Ink is applied thicker than digital printing, making your design more vibrant and easier to see on darker fabrics or surfaces.

Cons of Screen Printing as a Decoration Method

- The necessity to create screens means screen printing is not ideal for smaller order sizes or individually personalized items.

- Prices typically increase on orders with a high number of colors

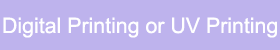

Digital Printing or UV Printing

An image is created with no restraints to the number of colors or type of artwork used, and the image is printed or affixed directly onto the material. With digital printing, full color, high definition logos can be done economically, even in small quantities.

When to Use Digital Printing as a Decoration Method

Commonly used as a substitute for screen printing on smaller orders, digital printing also works well with logos that require a high amount of detail or are very graphics heavy. This is also a commonly used option for logos that contain a gradient, as the print can closely match the digital version seen on a computer screen.

Digital Printing is Ideal for…

- Custom Electronics

- Custom Notebooks

- Custom Water Bottles & Drinkware

- Promotional Products

- Custom T-Shirts

- Custom Active wear & Sports Apparel

- Printed Sweatshirts & Hoodies

Pros of Digital Printing as a Decoration Method

- Easier set up than screen printing – no screen creation or color separation required.

- Ability to print more precise details in a broader range of colors.

- Great for smaller order sizes.

Cons of Digital Printing as a Decoration Method

- Digital Printing is typically more expensive than screen printing for large orders.

- Certain Direct to Garment Machines can only print on 100% cotton fabric.

- Digital Printing is slower than screen printing for large orders.

Pad Printing

Pad printing is a decoration technique in which ink is transferred from a silicone pad onto your desired surface. The pad printing process can be thought of as a more advanced version of stamping – a pad with ink is pressed onto the product and then left to air dry.

When to Use Pad Printing as a Decoration Method

Pad printing is a very versatile decoration method, in that it can be applied to just about any product regardless of shape or form. This makes it especially useful on rounded surfaces like golf balls, pens, and water bottles.

Pad Printing is Ideal for…

- Custom Logo Electronics

- Custom Notebooks and Stationary

- Personalized Golf Balls

- Custom Water Bottles & Drinkware

Pros of Pad Printing as a Decoration Method

- Superior image clarity.

- Easier than screen printing for printing on unusually shaped objects.

- Improved resolution on smaller fonts and designs over screen printing.

- Pad printing is a gentle decoration technique, making it ideal for delicate materials and fabrics.

- Low set-up costs and minimal equipment required.

Cons of Pad Printing as a Decoration Method

- Not ideal for designs with a lot of different colors.

- Pad printing process can be slow because you must change pads for each color and allow drying time.

- Typically, more expensive than screen printing.

Heat Transfer Printing

Transfer printing is used when an image has to be applied on a curved or uneven surface. Mostly, it is used for printing on materials like porcelain and cloth like surfaces. Transfer printing asks for designs to have full digital images with vector and high resolution bitmap images which can be applied on an array of products.

When to Use Heat Transfer as a Decoration Method

Transfer printing is a particularly popular method of decorating clothing items such as baseball caps. Baseball caps are difficult to print on because of the complications involved in printing on a curved surface. However, transfers for baseball caps can be printed very quickly and applied very easily, making perfect, economical promotional items.

Heat Transfer is Ideal for…

- Custom T-Shirts

- Custom Active wear & Sports Apparel

- Sweatshirts & Hoodies

- Custom Backpacks & Bags

- Custom Team wear

- Team Uniforms & Jerseys

Pros of Heat Transfer as a Decoration Method

- Minimal setup costs and equipment make heat transfers ideal for smaller order sizes.

- Affordable individually personalized decoration, such as sports uniforms.

- Allows for finer details and smaller text than embroidery.

- Heat transfer is available in many different finishes and styles.

- Environmentally friendly.

Cons of Heat Transfer as a Decoration Method

- Logos and designs larger than 15 inches tend to be more expensive than other design methods.

- An image does not last as long as some other decoration methods and the printed area is not very breathable.

- Unable to use an iron on the printed area of the garment.

- When logos are too large the texture of the design can be thrown off.

- Should not be done on certain synthetic materials that can’t be exposed to the high heat from the iron.

Laser Engraving

Engraving is a unique application where the laser removes a thin layer of fiber or pigment dye. By adjusting the intensity and speed of the laser we can sculpt dimension into the design, resulting in stunning clarity and precision.

There are two kinds of lasers:

A. Cool laser– used to engrave onto metal products. It operates like a mini-hammer that makes indentions at the surface of the metal surface. The indented part shows the inner color of the metal according to the design or pattern.

B. Heat laser- used to engrave onto non-metal products. It operates by focusing a light beam to the surface of the product and slightly burns the surface of the product according to the design or pattern.

When to Use Laser Engraving as a Decoration Method

This decoration method creates sharp, crystal-clear logos that are unable to be peeled off. Ideal for items that get continuous use such as promotional pens, custom drinkware, and personalized tools.

Laser Engraving is Ideal for…

- Custom Engraved Pens

- Custom Water bottles & Tumblers

- Engraved Mugs

- Custom Home Goods, Kitchenware & Tools

- Custom Flashlights

- Custom Multi-Tools & Pocket Knives

- Personalized Flasks

Pros of Laser Engraving as a Decoration Method

- Go-to decoration method for metal products.

- The engraving process itself is cheap and can be done very quickly.

- Designs are extremely durable, making them ideal for frequently handled items.

Cons of Laser Engraving as a Decoration Method

- Laser engraving machines are expensive.

- Laser engraving is typically only performed on metal or wood surfaces.

Debossing

Debossing and embossing gives your logo a 3-dimensional element. For both processes, dies are constructed from metal in the shape of your logo. The product is then placed between them and heat and pressure push and form the material into the impression you want. Embossing rises from the product, while debossing pushes into the product. For an additional cost, you can also add color to the logo.

When to Use Debossing as a Decoration Method

Perfect for products where subtle and high perceived value is appropriate. A crisp debossing adds lasting value to items used every day as well as unique dimension and quality to your product. Ideal products are leather goods such as pad folios, money clips, or luggage tags.

Debossing is Ideal for…

- Custom Notebooks & Journals

- Custom Home Goods & Tools

- Custom Leather Coasters

- Leather Wine Accessory Sets

- Custom Outerwear

- Personalized Leather Speakers

- Waterproof Apparel

Pros of Debossing as a Decoration Method

- Creates dimensional depth and detail by depressing your design onto the material.

- Doesn’t create holes in fabric like embroidery, making it ideal for water-proof apparel.

- Works extremely well on leather apparel or surfaces.

- Can be done in conjunction with other types of decoration.

Cons of Debossing as a Decoration Method

- Cannot be done across seams or zippers.

- Small text or highly detailed designs do not work as well with debossing.

Embroidery

Texturize your logo by choosing embroidery. Any cloth product, and especially corporate apparel, looks great with the vibrant stitching. In the embroidery process, your logo is changed to a digital image and then assigned color threads. Your garments or blankets are placed in the embroidery machine, the needles go to work, and then excess threads are cut off.

When to Use Embroidery as a Decoration Method

Embroidered logos typically look best on polos, jackets, woven shirts, caps, and bags, but this is a truly versatile style of decoration.

Embroidery is Ideal for…

- Custom Polo Shirts

- Custom Hats, Beanies & Visors

- Custom Jackets & Outerwear

- Custom Sweatshirts & Layering

- Custom Backpacks & Bags

- Custom Embroidered Towels & Blankets

- Much more

Pros of Embroidery as a Decoration Method

- There is an added texture to the design.

- The product does not need to be laid flat like in printing, making embroidery suitable for hats and bags.

- The intricate design evokes a high perceived value and sense of professionalism.

- More durable and resistant to damage from washing than most decoration methods.

Cons of Embroidery as a Decoration Method

- The number of colors used in the design is limited to the thread color options and prices typically increase with additional colors.

- Embroidery is only a suitable decoration method for fabric

- Embroidery machines can struggle with small lettering or fine details in the design.

Sticker (label) Printing

Using a sticker, it is the easiest way to add a logo. We can just use a normal printing machine to print on a sticker paper and stick it on the product.

Sticker Printing is Ideal for…

- Barcodes

- Glass bottle decoration

- Marking instructions

- Custom Notebooks & Journals

Pros of Sticker Printing as a Decoration Method

- Low Cost

- Work extremely well on any flat products’ surface

Cons of Sticker Printing as a Decoration Method

- Easily removed and can fall off

- Hard to positioning for every item

Crystal Epoxy Sticker Printing

The Crystal epoxy sticker printing is just like the sticker printing but with an additional feature. First, you print the sticker/label design, and then add AB glue on it. After the glue becomes solid, it will become “round” (like the water on a lotus leaf). With solid glue, the sticker has a more 3D feel and maintains the bright-colors.

Epoxy logo is Ideal for…

- Toys

- Jewelry

- Crafts

- Souvenir

- Personalized items like keychains, pins, ID cards

- Much More

Pros of Epoxy as a Decoration Method

- More luxurious and sturdy

- Waterproof and scratch resistant

- Longer lifespan

- Work extremely well on any flat products’ surface

Cons of Epoxy as a Decoration Method

- MOQ is higher

- Set up cost

- Hard to positioning for every item

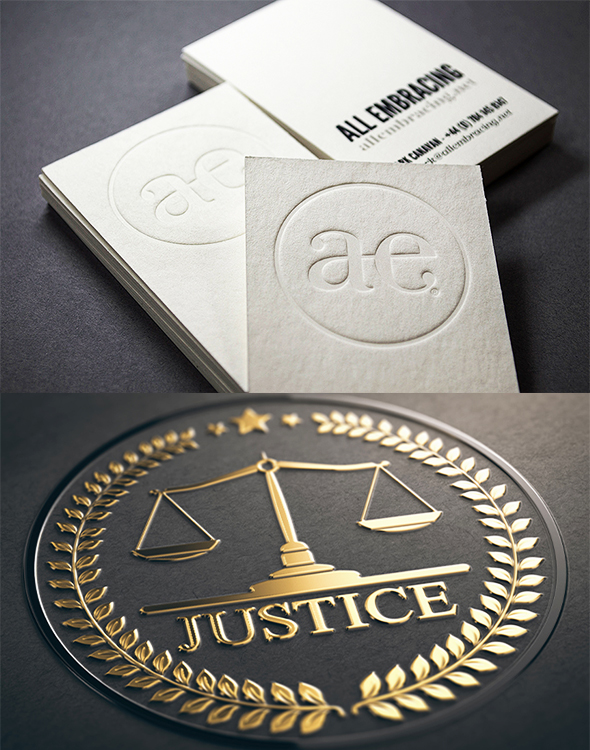

Foil Stamping

Foil stamping is a specialty printing process in which a metallic or pigmented foil is heated with a magnesium dye and then stamped with enough pressure to seal a thin layer of foil to the surface. Metallic foils are typically gold or silver and pigmented foils are most commonly red or black.

When to Use Foil Stamping as a Decoration Method

Metallic foils have a glossy, polished finish and are a great way to make your logo pop on darker colored surfaces. Because ink is not involved in the process, the color of your desired surface will not impact the design.

Foil Stamping is Ideal for…

- Custom Notebooks & Stationary

- Business Cards

- Invitations

- Dark Surfaces

Pros of Foil Stamping as a Decoration Method

- The polished and glossy finish stands out on any color surface.

- Foil stamping does not use ink, so the colors of your design will not be influenced by the surface color.

Cons of Foil Stamping as a Decoration Method

- Foil stamping is not a decoration method for apparel and is usually only utilized on hard goods.

- Can’t be used in conjunction with designs that use thermography because the heat from the foil stamping process will melt the resins

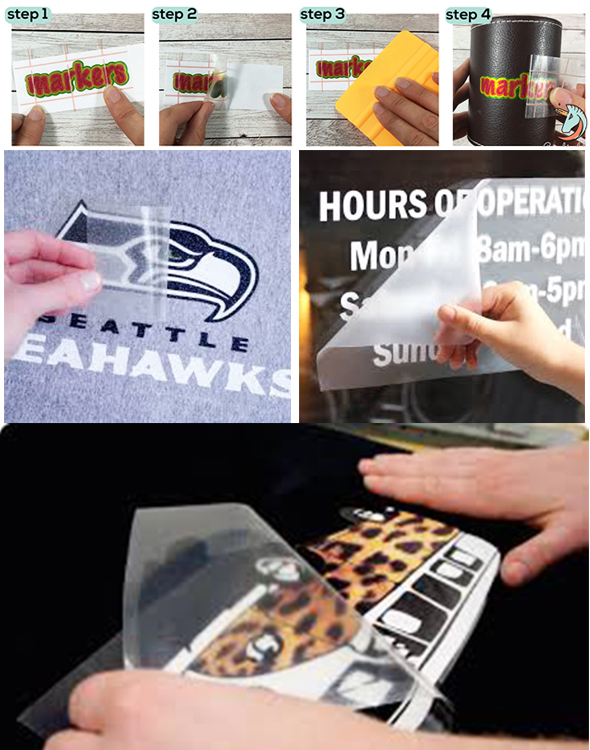

Vinyl Transfer

This transfer process uses heat to activate and attach a vinyl sticker to a fabric. Vinyl is soft to the touch with great stretch and is durable enough for sportswear.

When to Use Vinyl Transfer as a Decoration Method

Vinyl transfer has especially great durability. Perfect for uniforms and jerseys, as they are worn frequently and go through a lot of wear and tear. This decoration option is extremely dependable wash after wash.

Vinyl Transfer is Ideal for…

- Custom T-Shirts

- Custom Active wear & Sports Apparel

- Sweatshirts & Hoodies

- Custom Backpacks & Bags

Pros of Vinyl Transfer as a Decoration Method

- The image is long lasting and durable.

- Your company logo or custom design is easily applied to any fabric or material that can absorb color.

- Vinyl transfer is a very affordable decoration method.

Cons of Vinyl Transfer as a Decoration Method

- Preparing the vinyl design can be time-consuming.

- It is possible to add multiple colors to your design, but it requires you to layer solid colors to get there and that just adds time to the process.